Case Studies

Paper & Pulp / GearBox

Wireless Condition Monitoring Predicts Failure of Calendar Roll Gearbox; Extends the Roller Life and Saves USD 60 Thousand

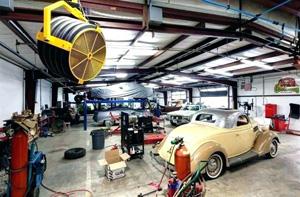

Automotive / Motor

Smart Condition Monitoring Saves USD 30 Thousand by Predicting Failure of the Motor Pulley System

Forging / Press

Pitman Breakage Predicted on 5000 Ton Forging Press Saving USD 500 Thousand

Automotive / Motor

USD 1.2 Million Saved on a Forging Press Line by Predicting Cutter Life and Preventing Gearbox Failure on Circular Saw

Packaging / Motor

Intelligent IoT Device Conserves Life of 7.5HP Chiller Circulating Pump and Profits the Manufacturer With USD 26 Thousand in a Fabric Plant

Automotive / Bandsaw Cutter

USD 1.2 Million Saved on a Forging Press Line by Predicting Cutter Life and Preventing Gearbox Failure on Circular Saw

Forging / Main Motor

Remote Condition Monitoring Avoids Production Loss of 11 Days; Ensures Timely Delivery of 1,50,000 Forging Components

Forging / Motor

German Automotive Forging Components Manufacturer Avoided Major Motor Failure Resulting in Preventing an Eminent Production Loss of USD 700 Thousand

Automotive / Motor Coupling

Plug and Play IoT Solution Saves HDC 40 Ton Motor in Tube Production Plant Saving USD 72 Thousand

Automotive / Exhaust Fan

Smart IoT Solution Predicts Unbalance in Exhaust Fan in the Paint Shop Saving

Automotive / Paint Shop-Motor

Smart IoT Gadget Saved a Major Failure in Assembly Line of Paint Shop at Leading Two-wheeler Manufacturer and Benefited USD 40 Thousand Per Hour

Engineering / Spindle-Bearing

Wireless Condition Monitoring Tool Ensures Availability of CNC Grinding Machine; Ensures Production Fulfillment of USD 36 Thousand

Automotive / Grinding Machine

Smart Condition Monitoring Tool Predicted The Tool Failure Of A M601 Grinding Machine; Thereby Saved USD 20 Thousand

Automotive / Trimming Press

Smart Condition Monitoring Tool Saved USD 10 Thousand By Predicting Failure Of 1001 Trimming Machine

Automotive / Motor Belt

USD 30 Thousand Saved on a 4000 T Press in an Automotive Component Manufacturing Plant

FMCG / Scrubber Pump

Prediction of Scrubber Pump Motor Breakdown Saves USD 25 Thousand in FMCG Company

Automotive / Predictive Maintenance

24 Hours of Unplanned Downtime Saved USD 1 Million for a Single Machine in Manufacturing Facility

Automobile / Duplex Milling Machine

Root Cause Analysis For Spindle Failure Saves USD 58 Thousand Per Hour In A Fortune 500 Automobile Plant

Automotive / Spline Rolling Machine

Predictive Maintenance Saves USD 8000 on A Single Spline Rolling Machine

Chemical / Cooling Tower-Fan

Zero Downtime For A Cooling Tower Saves USD 80 Thousand In A Chemical Plant

Automotive / Spindle-Overload

Smart Plug And Play Condition Monitoring Tool Predicts The Overloading Of The Spindle; Subsequently Prevents The Bearing Failure And Saves

Automotive / Decoiler

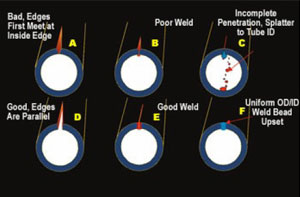

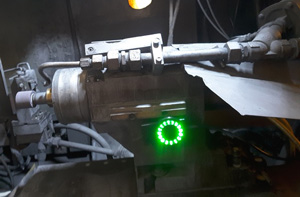

Zero Downtime For Raw Material Handling Saves USD 1500 Per Hour In A Tube Plant

Automotive / Plummerblock

Plug And Play Vibration Monitoring Solution Avoided Downtime In A Conglomerate Organisation; Saves USD 17 Thousand

Automotive / Forging-Press

Predictive Maintenance End-to-end Solution Remotely Supervised 2500T Hot Forging Press And Significantly Prevented Breakdown In The Plant

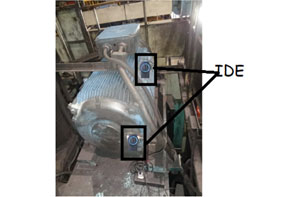

Steel / Mill Crusher

Industry 4.0 Solution Prevents A Severe Breakdown Of A Hammer Mill Crusher In A Steel Plant; Saves USD 6 Thousand And 4 Hours Production Downtime